Fluids and Process Engineering improvements

FLUID/SLURY PROCESS IMPROVEMENTS

Optimizing floc and lime systems involves a combination of technical expertise, advanced engineering, and continuous improvement practices. By focusing on efficient chemical usage, precise system design, and robust process control, plants can achieve maximum efficiency, reduce operational costs, and contribute to environmental sustainability.

Process Analysis and Diagnostics

- Current System Evaluation: Conduct a thorough assessment of the existing floc and lime systems. Identify bottlenecks, inefficiencies, and areas of excessive chemical usage.

- Data Collection: Gather data on flow rates, chemical dosages, water quality parameters, and sludge production. Use this data to create a baseline for performance metrics.

Optimized Chemical Usage

- Chemical Interactions: Study the interactions between flocculants and lime with the specific wastewater or process stream. Select the most effective chemicals and dosages to achieve the desired treatment objectives with minimal waste.

- Polymer Selection: Use advanced polymer selection techniques to choose the right type and concentration of flocculants. This can significantly reduce the amount of polymer required while improving the clarity of treated water.

FLUID/SLURY PROCESS IMPROVEMENTS

Optimizing floc and lime systems involves a combination of technical expertise, advanced engineering, and continuous improvement practices. By focusing on efficient chemical usage, precise system design, and robust process control, plants can achieve maximum efficiency, reduce operational costs, and contribute to environmental sustainability.

Process Analysis and Diagnostics

- Current System Evaluation: Conduct a thorough assessment of the existing floc and lime systems. Identify bottlenecks, inefficiencies, and areas of excessive chemical usage.

- Data Collection: Gather data on flow rates, chemical dosages, water quality parameters, and sludge production. Use this data to create a baseline for performance metrics.

Optimized Chemical Usage

- Chemical Interactions: Study the interactions between flocculants and lime with the specific wastewater or process stream. Select the most effective chemicals and dosages to achieve the desired treatment objectives with minimal waste.

- Polymer Selection: Use advanced polymer selection techniques to choose the right type and concentration of flocculants. This can significantly reduce the amount of polymer required while improving the clarity of treated water.

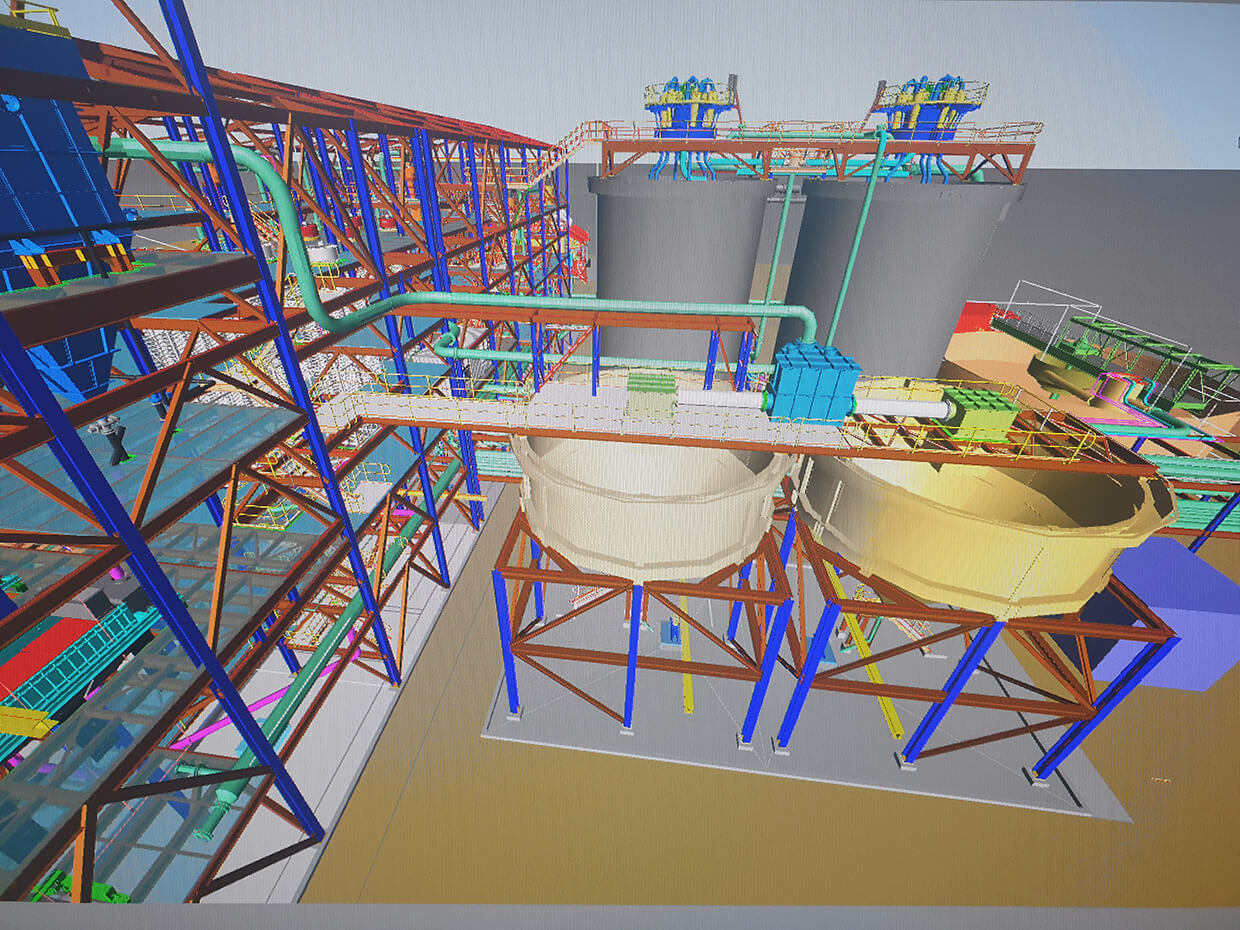

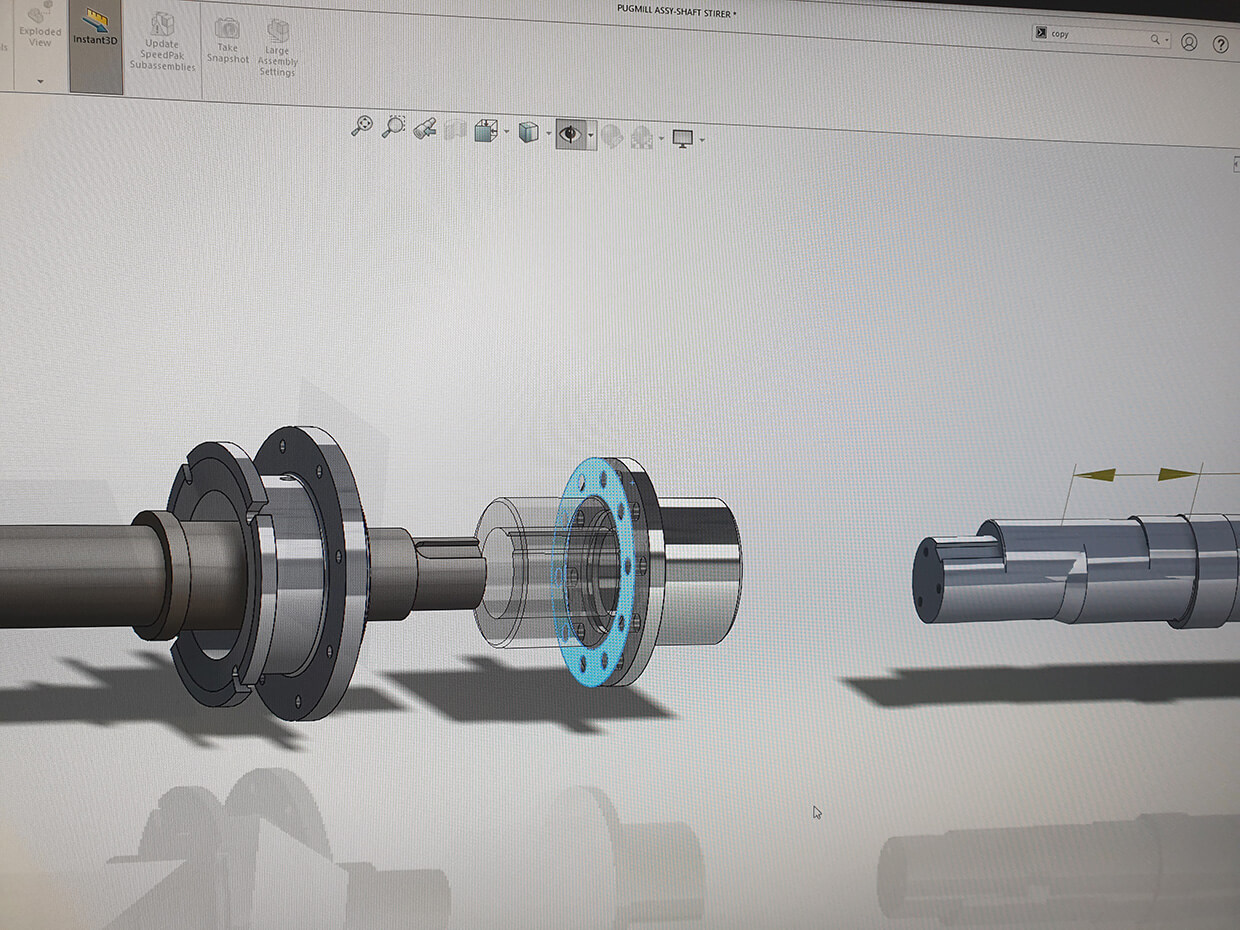

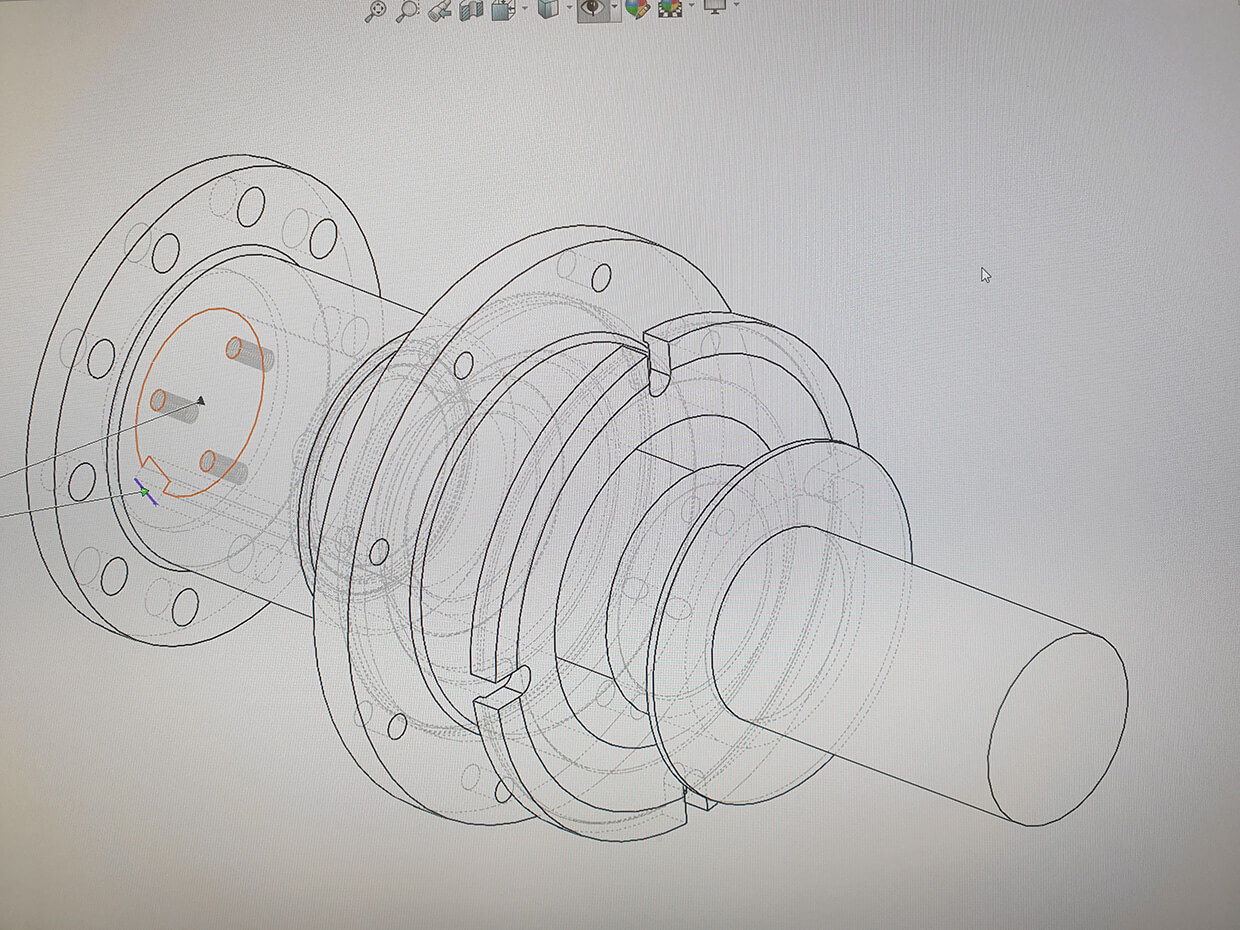

Equipment and System Design

- Injection Systems: Design and optimize injection systems for precise delivery of flocculants and lime. Ensure uniform mixing and distribution to enhance the treatment process.

- Pumping Solutions: Implement pumps that are specifically designed for handling floc and lime. Consider factors like flow rate, pressure, and the nature of the chemicals to select appropriate pumps that minimize wear and tear.

Water Reuse and Conservation

- Effluent Treatment: Enhance the treatment of effluent streams to improve the quality of discharge water, making it suitable for reuse within the plant.

- Sludge Management: Optimize sludge handling processes to reduce water content in sludge, thereby minimizing disposal costs and recovering more water for reuse.

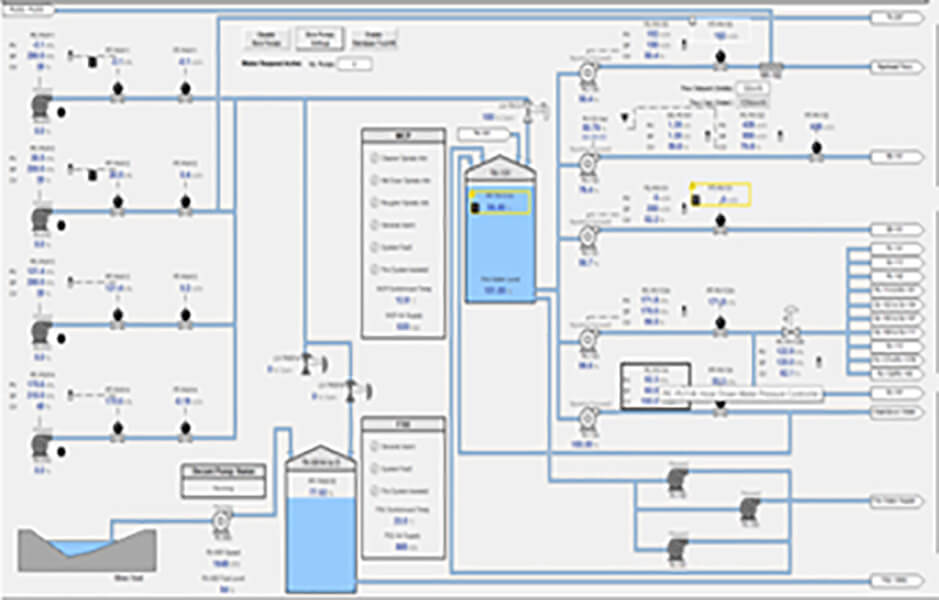

Automation and Control

- Process Control Systems: Implement advanced control systems to automate the dosing and mixing processes. Use sensors and feedback loops to maintain optimal conditions in real-time.

- Monitoring and Reporting: Install monitoring systems to track the performance of the floc and lime systems continuously. Generate reports that help in making data-driven decisions for further improvements.

- Standard Operating Procedures: Develop and implement best practice standard operating procedures (SOPs) for the operation and maintenance of floc and lime systems.

- Staff Training: Train plant personnel on the latest techniques and technologies in chemical handling, system operation, and emergency response to ensure safe and efficient plant operations.

Environmental and Economic Benefits

- Cost Savings: By optimizing chemical usage and improving system efficiency, significant cost savings can be achieved. These savings come from reduced chemical consumption, lower sludge disposal costs, and decreased energy usage.

- Environmental Impact: Enhanced treatment processes lead to better effluent quality, reducing the environmental impact of the plant’s discharge. Additionally, water conservation efforts contribute to sustainable water management practices.

- Standard Operating Procedures: Develop and implement best practice standard operating procedures (SOPs) for the operation and maintenance of floc and lime systems.

- Staff Training: Train plant personnel on the latest techniques and technologies in chemical handling, system operation, and emergency response to ensure safe and efficient plant operations.

Environmental and Economic Benefits

- Cost Savings: By optimizing chemical usage and improving system efficiency, significant cost savings can be achieved. These savings come from reduced chemical consumption, lower sludge disposal costs, and decreased energy usage.

- Environmental Impact: Enhanced treatment processes lead to better effluent quality, reducing the environmental impact of the plant’s discharge. Additionally, water conservation efforts contribute to sustainable water management practices.

Implementation Steps

1. Audit: Start with a comprehensive audit of the current systems.

2. Pilot Testing: Conduct pilot tests to validate proposed changes and optimizations.

3. Design and Engineering: Develop detailed designs for optimized systems and procure necessary equipment.

4. Installation and Commissioning: Implement the new systems and ensure they are properly commissioned.

5. Performance Monitoring: Continuously monitor the performance of the optimized systems and make adjustments as necessary.

Sustainability

1. Minimizing Our Carbon Footprint: We prioritize initiatives aimed at reducing our environmental impact, including energy efficiency measures, waste reduction efforts, and adoption of renewable energy sources.

2. Enabling a Low-Carbon Society: We actively contribute to the transition towards a low- carbon society by developing and implementing innovative solutions that promote sustainability across industries.

3. Engaging Our Employees and Communities: We recognize the importance of collective action in building a more inclusive and sustainable future. Through community outreach programs, employee engagement initiatives, and partnerships with local stakeholders, we work towards fostering positive change and creating lasting impact.

At the heart of our sustainability efforts lies a commitment to environmental stewardship, social responsibility, and economic prosperity. By aligning our actions with these principles, we strive to create a better world for current and future generations.

1. Minimizing Our Carbon Footprint: We prioritize initiatives aimed at reducing our environmental impact, including energy efficiency measures, waste reduction efforts, and adoption of renewable energy sources.

2. Enabling a Low-Carbon Society: We actively contribute to the transition towards a low- carbon society by developing and implementing innovative solutions that promote sustainability across industries.

3. Engaging Our Employees and Communities: We recognize the importance of collective action in building a more inclusive and sustainable future. Through community outreach programs, employee engagement initiatives, and partnerships with local stakeholders, we work towards fostering positive change and creating lasting impact.

At the heart of our sustainability efforts lies a commitment to environmental stewardship, social responsibility, and economic prosperity. By aligning our actions with these principles, we strive to create a better world for current and future generations.